|

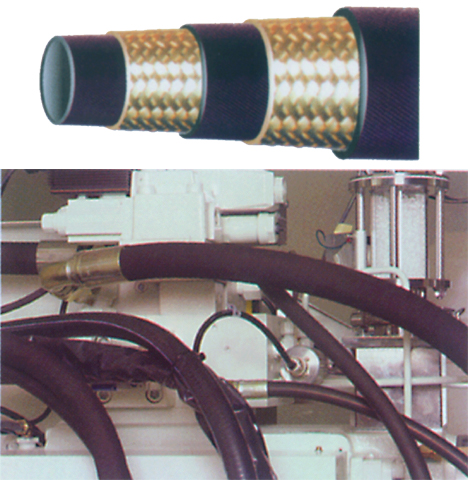

High Pressure Steel Wire Braided Hose |

| Company Profile | Product Center | Contact Us | Mail Box | Back Index | 简体中文/English |

High Pressure Steel Wire Braided Hose |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| This product is used mainly for hydraulic power transmission or for delivery of water, gas, oil and other high pressure media at operating temperature of -40℃~+100℃.It is made from the latest nanometer material, providing good resistance to oil, ozone and aging, and high pulse performance. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic parameters for steel wire braided hose Application standard: GB/T3683-92 MY98-84

|

| ADD:0907 SUITE, 1ST BUILDING, 19 CHUANGYE ST., TAIYUAN XUEFUYUAN ZONE, SHANXI ZONGGAISHIFAN ZONE, 030006, TAIYUAN, SHANXI, CHINA |

| TEL:0086-351-5600630, 5600631; E-mail: worgxp@sxyixing.com; CONTACT:MR GUO XIAOPING |

|