| |

The Standards Of Pipe Fittings |

|

| |

Reference Standard

Standard Code |

Standard Name |

ASME B16.9 |

Factory-made wrought steel butt-welding fittings |

ASME B16.5 |

Pipe flanges and flanged fittings |

ASME B16.11 |

Forged fittings socket-welding and threaded |

ASME B16.47 |

Steel flanges |

ASME B16.28 |

Wrought steel butt-welding short radius elbows and returns |

MSS-SP-43 |

Wrought stainless steel butt-welding fittings |

MSS-SP-44 |

Steel flanges |

MSS-SP-75 |

Specification for high test wrought butt welding fittings |

MSS-SP-79 |

Socket-welding reducer inserts |

MSS-SP-83 |

Class 3000 steel pipe unions socket-welding and threaded |

MSS-SP-95 |

Swage(d)nipples and Circle plugs |

MSS-SP-97 |

Integrally reinforced forged branch outlet fittings-socket welding,threaded and butt-welding ends |

ANSI/AWWA C207 |

Steel Pipe Flanges For Waterworks Service |

|

|

| |

Flanges |

|

| |

ANSI B16.5 Welding Neck |

ANSI B16.5 Slip-On |

|

| |

ANSI B16.5 Threaded |

ANSI B16.5 Lap Joint |

|

| |

ANSI B16.5 Socket Welding |

ANSI B16.5 Blind |

|

| |

ASME B16.47 Series B API 605 Welding Neck

ASME B16.47 Series B API 605 Welding Neck |

ASME B16.47 Series A MSS SP-44 Pipe Line Flange

ASME B16.47 Series A MSS SP-44 Pipe Line Flange |

|

| |

ANSI B16.36 Forged Orifice Welding Neck

ANSI B16.36 Forged Orifice Welding Neck |

ANSI B16.36 Forged Orifice Slip-On

ANSI B16.36 Forged Orifice Slip-On |

ANSI B16.36 Forged Orifice Threaded

ANSI B16.36 Forged Orifice Threaded |

|

|

| |

|

|

| |

API Flanges |

|

| |

Studded Type Threaded Companion Flange |

Through Bolted Type Threaded Companion Flange |

|

| |

PHYSICAL AND CHEMICAL PROPERTIES

Property |

Type 1 |

Type 2 |

Type 3 |

Type 4 |

Tensile strength, min., psi Mpa) |

70,000(483) |

90,000(621) |

100,000(690) |

70,000(483) |

Yield strength, min., psi (Mpa) |

36,000(248) |

60,000(414) |

75,000(517) |

45,000(310) |

Elongation in 2 in., min., percent |

22 |

18 |

17 |

19 |

Reduction in area, min., percent |

30 |

35 |

35 |

32 |

Carbon, max., percent |

- |

- |

- |

0.35 |

Manganese, max., percent |

- |

- |

- |

0.9 |

Sulfur, max., percent |

- |

- |

- |

0.05 |

Phosphorus, max., percent |

- |

- |

- |

0.05 |

|

|

| |

|

|

|

| |

ANSI, MSS and API standards govern flange dimensions and tolerances. ANSI B16.5,titled "Steel Pipe Flanges and Flanged Fittings", is the basic standard. It covers forged steel flanges, sizes NPS 1/2(DN 15) through NPS 24(DN 600). ANSI B16.36 covers Orifice Flanges. The following MSS and API standards are written to supplement B16.5:

MSS SP-6: Flange facings

MSS SP-9: Spot facing for bronze, iron and steel flanges

MSS SP-25: Marking of flanges

MSS SP-39: Bolts and nuts for flanges

MSS SP-44: Large diameter pipe line flanges NPS 22 (DN 550) and NPS 26 (DN 650) through NPS 36(DN 900).

API 6A: Wellhead equipment

API 605: Large diameter flanges for petroleum usage NPS 26(DN 650) through NPS 60(DN 1500)

AWWA C207: Hub flanges |

|

| |

Flanges Material |

|

| |

LIST OF MATERIAL SPECIFICATIONS

Material

Group |

Nominal Designation |

Pressure-Temperature Rating Table |

Applicable ASTM Specifications |

Forgings |

Castings |

Plates |

1.1 |

C-Si |

2002.1.1 |

A 105 |

A 216 Gr. WCB |

A 515 Gr.70 |

|

C-Mn-Si |

|

A 350 Gr.LF2 |

|

A 516 Gr.70 |

|

|

|

|

|

A 537 Cl.1 |

1.2 |

C-Mn-Si |

2002.1.2 |

|

A 216 Gr.WCC |

|

|

|

|

|

A 352 Gr.LCC |

|

|

2?Ni |

|

|

A 352 Gr.LC2 |

A 203 Gr.B |

|

3?Ni |

|

A 350 Gr. LF3 |

A 352 Gr.LC3 |

A 203 Gr.E |

1.3 |

C-Si |

2002.1.3 |

|

A 352 Gr. LCB |

A 515 Gr.65 |

|

C-Mn-Si |

|

|

|

A 516 Gr.65 |

|

2?Ni |

|

|

|

A 203 Gr.A |

|

3?Ni |

|

|

|

A 203 Gr.D |

1.4 |

C-Si |

2002.1.4 |

|

|

A 515 Gr.60 |

|

C-Mn-Si |

|

A 350 Gr. LF1 Cl.1 |

|

A 516 Gr.60 |

1.5 |

C-?Mo |

2002.1.5 |

A 182 Gr.F1 |

A 217 Gr. WC1 |

A 204 Gr.A |

|

|

|

|

A 352 Gr.LC1 |

A 204 Gr.B |

1.7 |

C-?Mo |

2002.1.6 |

|

|

A 204 Gr.C |

|

?Cr-?Mo |

|

A 182 Gr. F2 |

|

|

|

Ni-?Cr-1/2Mo |

|

|

A 217 Gr. WC4 |

|

|

?Ni-?Cr-1Mo |

|

|

A 217 Gr.WC5 |

|

1.9 |

1Cr-?Mo |

2002.1.9 |

A 182 Gr.F12 Cl.2 |

|

|

|

1?Cr-?Mo |

|

|

A 217 Gr. WC6 |

|

|

1?Cr-?Mo-Si |

|

A 182 Gr. F11 Cl.3 |

|

A 387 Gr. 11 Cl.2 |

1.1 |

2?Cr-1Mo |

2002.1.10 |

A 182 Gr. F22 Cl.3 |

A 217 Gr. WC9 |

A 387 Gr. 22 Cl.2 |

1.13 |

5Cr-?Mo |

2002.1.13 |

A 182 Gr.F5 |

|

|

|

|

|

A 182 Gr.F5a |

A 217 Gr.C5 |

|

1.14 |

9Cr-1Mo |

|

A 182 Gr.F9 |

A 217 Gr.C12 |

|

2.1 |

18Cr-8Ni |

2002.2.1 |

A 182 Gr.F304 |

A 351 Gr.CF3 |

A 240 Gr.304 |

|

|

|

A 182 Gr.F304H |

A 351 Gr.CF8 |

A 240 Gr.304H |

2.2 |

16Cr-12Ni-2Mo |

2002.2.2 |

A 182 Gr.F316 |

A 351 Gr.CF3M |

A 240 Gr.316 |

|

|

|

A 182 Gr.F316H |

A 351 Gr.CF8M |

A 240 Gr.316H |

|

18Cr-13Ni-3Mo |

|

|

|

A 240 Gr.317 |

|

19Cr-10Ni-3Mo |

|

|

A 351 Gr.CG8M |

|

2.3 |

18Cr-8Ni |

2002.2.3 |

A 182 Gr.F304L |

|

A 240 Gr.304L |

|

16Cr-12Ni-2Mo |

|

A 182 Gr.F316L |

|

A 240 Gr.316L |

2.4 |

18Cr-10Ni-Ti |

2002.2.4 |

A 182 Gr.F321 |

|

A 240 Gr.321 |

|

|

|

A 182 Gr.F321H |

|

A 240 Gr.321H |

2.5 |

18Cr-10Ni-Cb |

2002.2.5 |

A 182 Gr.F347 |

A 351 Gr.CH8C |

A 240 Gr.347 |

|

|

|

A 182 Gr.F347H |

|

A 240 Gr.347H |

|

|

|

A 182 Gr.F348 |

|

A 240 Gr.348 |

|

|

|

A 182 Gr.F348H |

|

A 240 Gr.348H |

2.6 |

25Cr-12Ni |

2002.2.6 |

|

A 351 Gr.CH8 |

|

|

|

|

|

A 351 Gr.CH20 |

|

|

23Cr-12Ni |

|

|

|

A 240 Gr.309S |

|

|

|

|

|

A 240 Gr.309H |

2.7 |

25Cr-20Ni |

2002.2.7 |

A 182 Gr.F310 |

A 351 Gr.CK20 |

A 240 Gr.310S |

|

|

|

|

|

A 240 Gr.310H |

2.8 |

20Cr-18Ni-6Mo |

2002.2.8 |

A 182 Gr.F44 |

A 351 Gr.CK3MCuN |

A 240 Gr.S31254 |

|

22Cr-5Ni-3Mo-N |

|

A 182 Gr.F51 |

|

A 240 Gr.S31803 |

|

25Cr-7Ni-4Mo-N |

|

A 182 Gr.F53 |

|

A 240 Gr.S32750 |

3.1 |

35Ni-35Fe-20Cr-Cb |

2002.3.1 |

B 462 Gr.N08020 |

|

B 463 Gr.N08020 |

|

28Ni-19Cr-Cu-Mo |

|

|

A 351 Gr.CN7M |

|

3.2 |

99.0Ni |

2002.3.2 |

B 160 Gr.N02200 |

|

B 162 Gr.N02200 |

3.3 |

99.0Ni-Low C |

2002.3.3 |

B 160 Gr.N02201 |

|

B 162 Gr.N02201 |

3.4 |

67Ni-30Cu |

2002.3.4 |

B 564 Gr.N04400 |

|

B 127 Gr.N04400 |

|

67Ni-30Cu-S |

|

B 164 Gr.N04405 |

|

|

3.5 |

72Ni-15Cr-8Fe |

2002.3.5 |

B 564 Gr.N06600 |

|

B 168 Gr.N06600 |

3.6 |

33Ni-42Fe-21Cr |

2002.3.6 |

B 564 Gr.N08800 |

|

B 409 Gr.N08800 |

3.7 |

65Ni-28Mo-2Fe |

2002.3.7 |

B 335 Gr.N10665 |

|

B 333 Gr.N10665 |

3.8 |

54Ni-16Mo-15Cr |

2002.3.8 |

B 564 Gr.N10276 |

|

B 575 Gr.N10276 |

|

60Ni-22Cr-9Mo-3.5Cb |

|

B 564 Gr.N06625 |

|

B 443 Gr.N06625 |

|

62Ni-28Mo-5Fe |

|

B 335 Gr.N10001 |

|

B 333 Gr.N10001 |

|

70Ni-16Mo-7Cr-5Fe |

|

B 573 Gr.N10003 |

|

B 434 Gr.N10003 |

|

61Ni-16Mo-16Cr |

|

B 574 Gr.N06455 |

|

B 575 Gr.N06455 |

|

42Ni-21.5Cr-3Mo-2.3Cu |

|

B 564 Gr.N08825 |

|

B 424 Gr.N08825 |

3.9 |

47Ni-22Cr-9Mo-18Fe |

2002.3.9 |

B 572 Gr.N06002 |

|

B 435 Gr.N06002 |

3.1 |

25Ni-46Fe-21Cr-5Mo |

2002.3.10 |

B 672 Gr.N08700 |

|

B 599 Gr.N08700 |

3.11 |

44Fe-25Ni-21Cr-Mo |

2002.3.11 |

B 649 Gr.N08904 |

|

B 625 Gr.N08904 |

3.12 |

26Ni-43Fe-22Cr-5Mo |

2002.3.12 |

B 621 Gr.N08320 |

|

B 620 Gr.N08320 |

|

47Ni-22Cr-20Fe-7Mo |

|

B 581 Gr.N06985 |

|

B 582 Gr.N06985 |

3.13 |

49Ni-25Cr-18Fe-6Mo |

2002.3.13 |

B 581 Gr.N06975 |

|

B 582 Gr.N06975 |

|

Ni-Fe-Cr-Mo-Low Cu |

|

B 564 Gr.N08031 |

|

B 625 Gr.N08031 |

3.14 |

47Ni-22Cr-19Fe-6Mo |

2002.3.14 |

B 581 Gr.n06007 |

|

B 582 Gr.N06007 |

3.15 |

33Ni-42Fe-21Cr |

2002.3.15 |

B 564 Gr.N08810 |

|

B 409 Gr.N08810 |

3.16 |

35Ni-19Cr-1?Si |

2002.3.16 |

B 511 Gr.N08330 |

|

B 536 Gr.N08330

|

|

|

| |

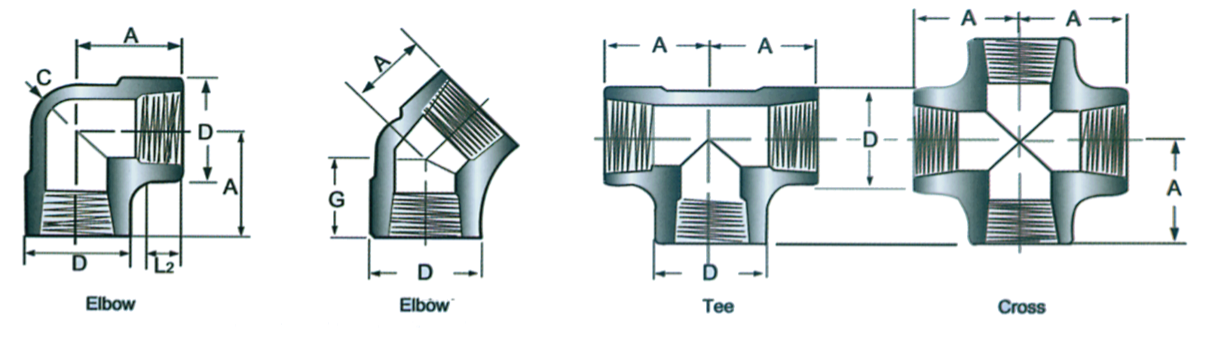

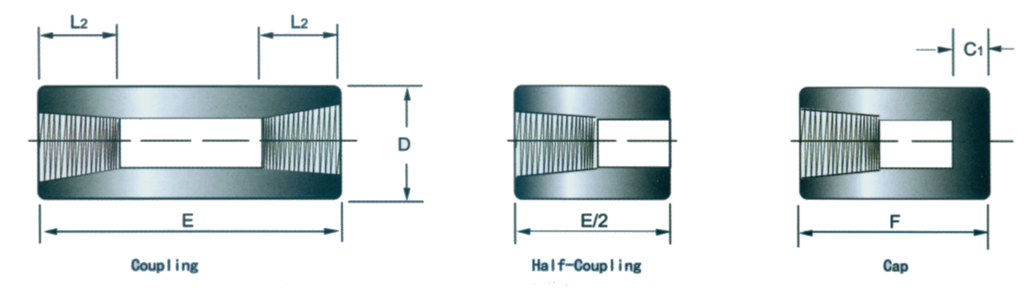

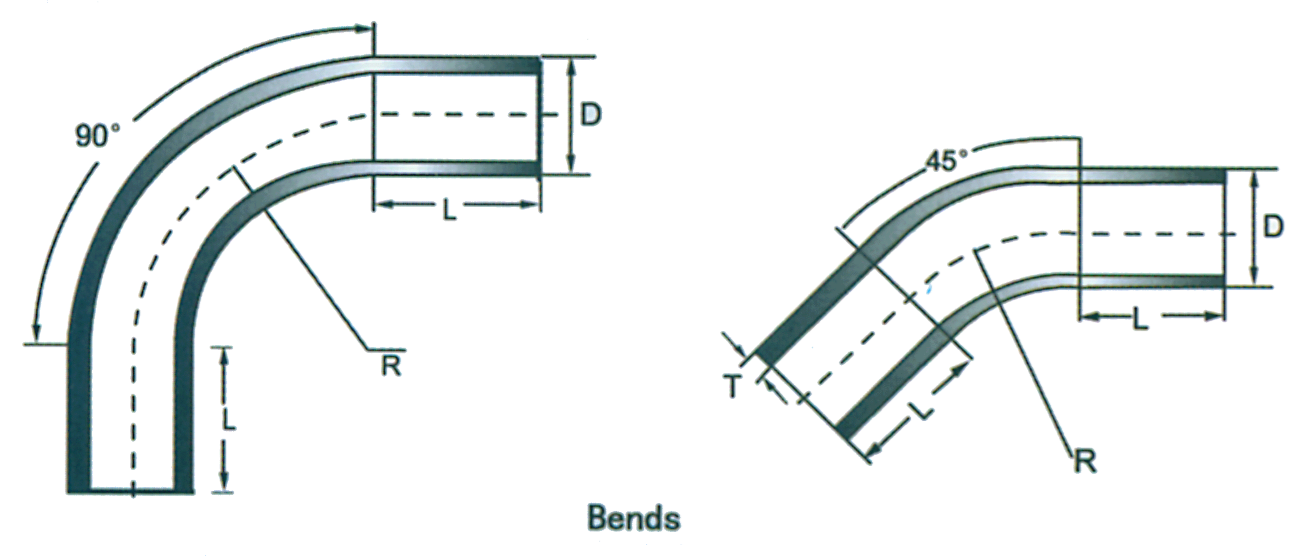

High Pressure Forged Fittings (SW,BW,THRD) |

|

| |

|

Product description:

45° 90° 180°LR&SR Elbow,Tee,Cross,Reducer,

Plugs &Caps,union,outlet,Elbolet ,Latrolet ,Nipolet ,Boss, Nipples,Coupling

Production range:DN8-DN400 (1/8”-16”)

Pressure Rate:2000Lb,3000Lb,6000Lb,9000Lb

Manufacturing standard: GB/T 14383, SH3410, HG/T21634, ASME B16.11,JISB 2316, MSS SP83,MSS SP-79,MSS-SP97,DIN

Material:

Stainless steel

0Cr19Ni19,0Cr18Ni9Ti,1Cr18Ni9Ti,0Cr18Ni12Mo2Ti, 00Cr18Ni10,00Cr19Ni11,00Cr17Ni14Mo2,F304/304L, F316/316L,F321,F321H,F317L,F310,A182,F44(UNS31254)

Duplex & Super Stainless Steel

A182 F51/UNS31803,F53/UNS32750,F55/UNS32760

Carbon Steel

20#, A105,A350LF1/LF2/LF3,MSS SP44 & A694 F42/46/52/60/65/70

Alloy Steel

A182 F1/F5a/F9/F11/F12/F22/F91

Others

Copper-Nickle Alloy,Titanium,Aluminum,Monel, Inconel,Hastelloy and other special material. |

|

| |

Socket Welding Fittings

|

|

| |

Socket Welding Reducer Inserts

|

|

| |

Unions of Socket-Welding & Threaded

|

|

| |

SW Outlets & THD Outlets

|

|

| |

Weldolet

|

|

| |

Nipolets

|

|

| |

|

|

| |

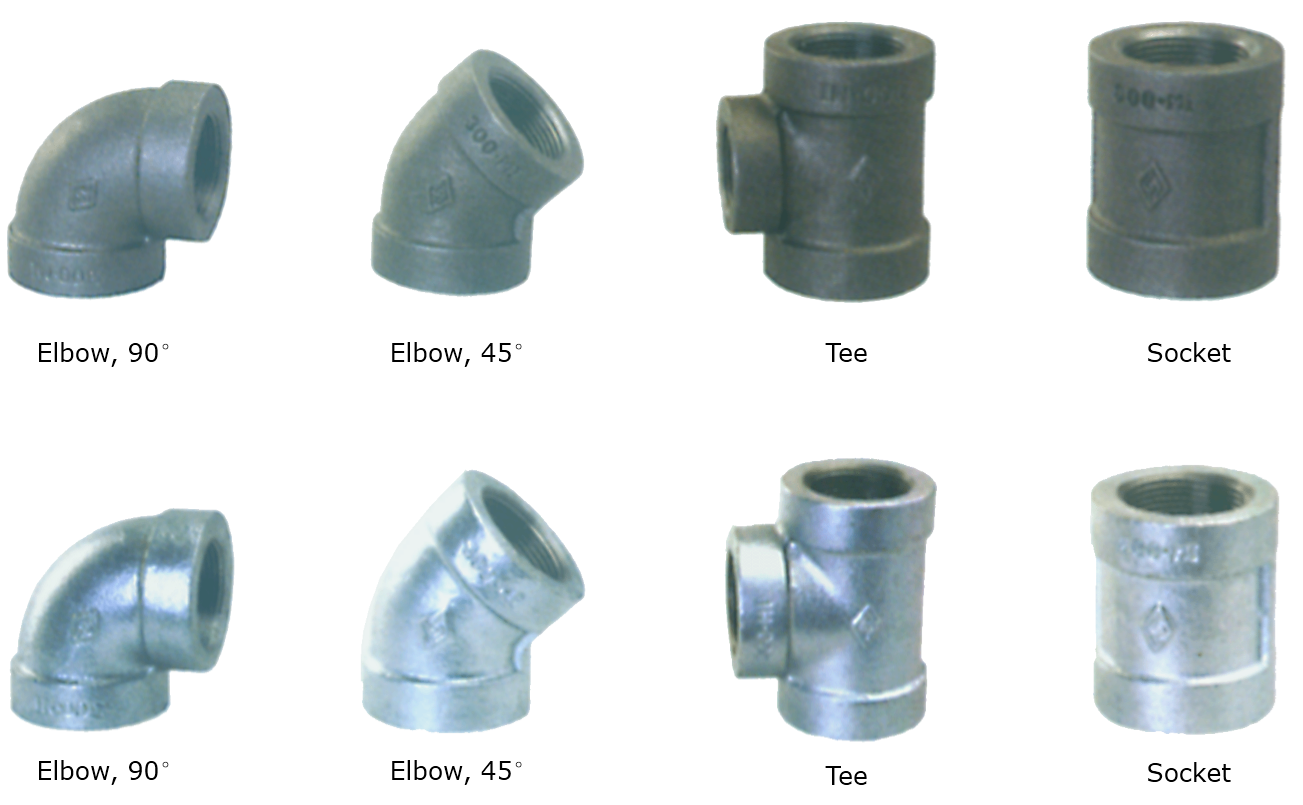

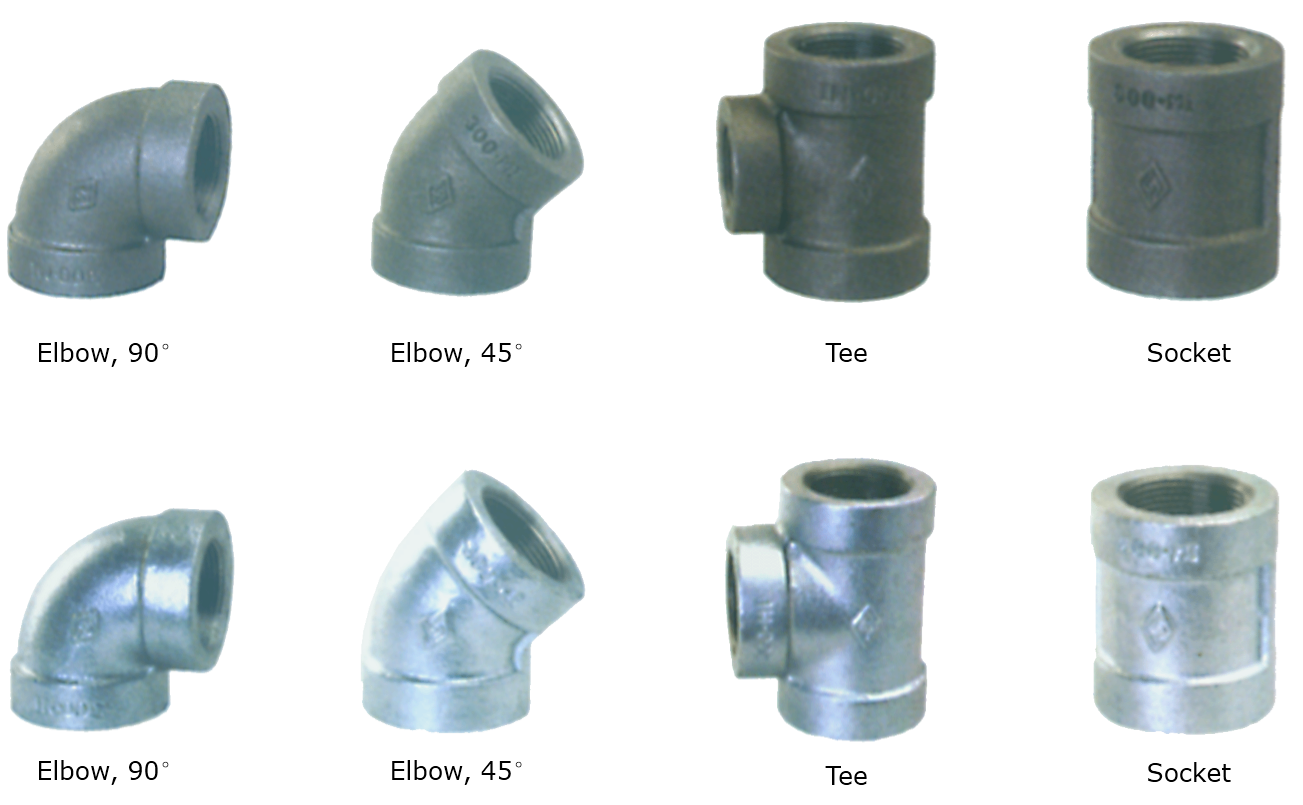

Threaded Fitting

|

|

| |

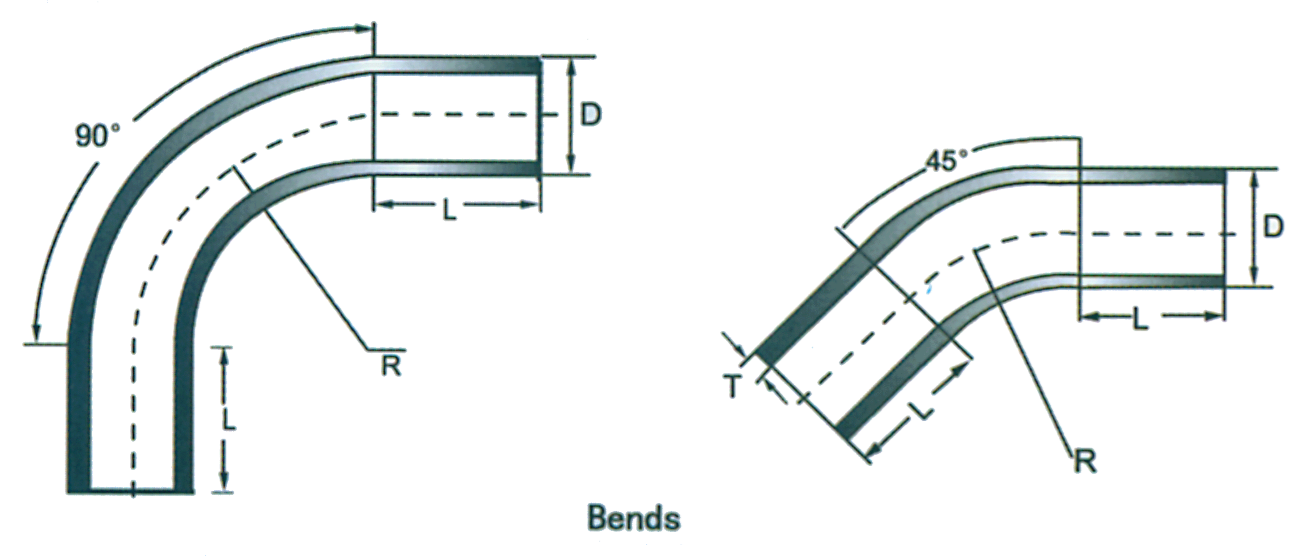

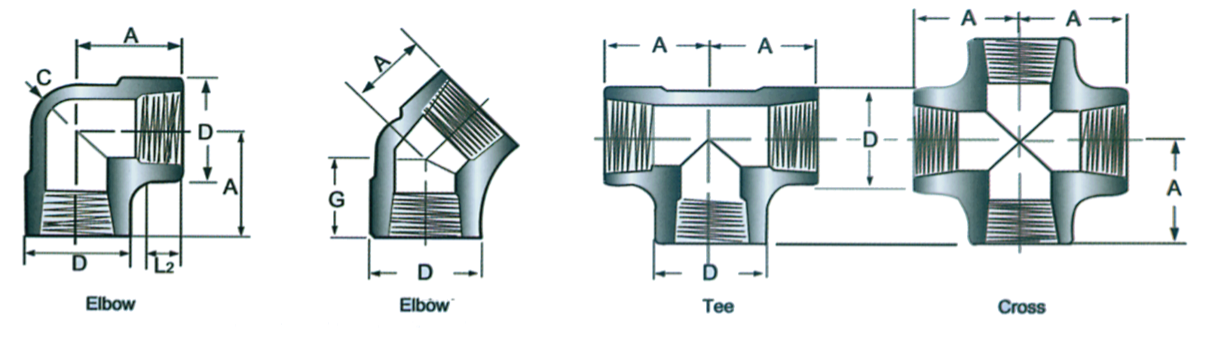

Bends

|

|

| |

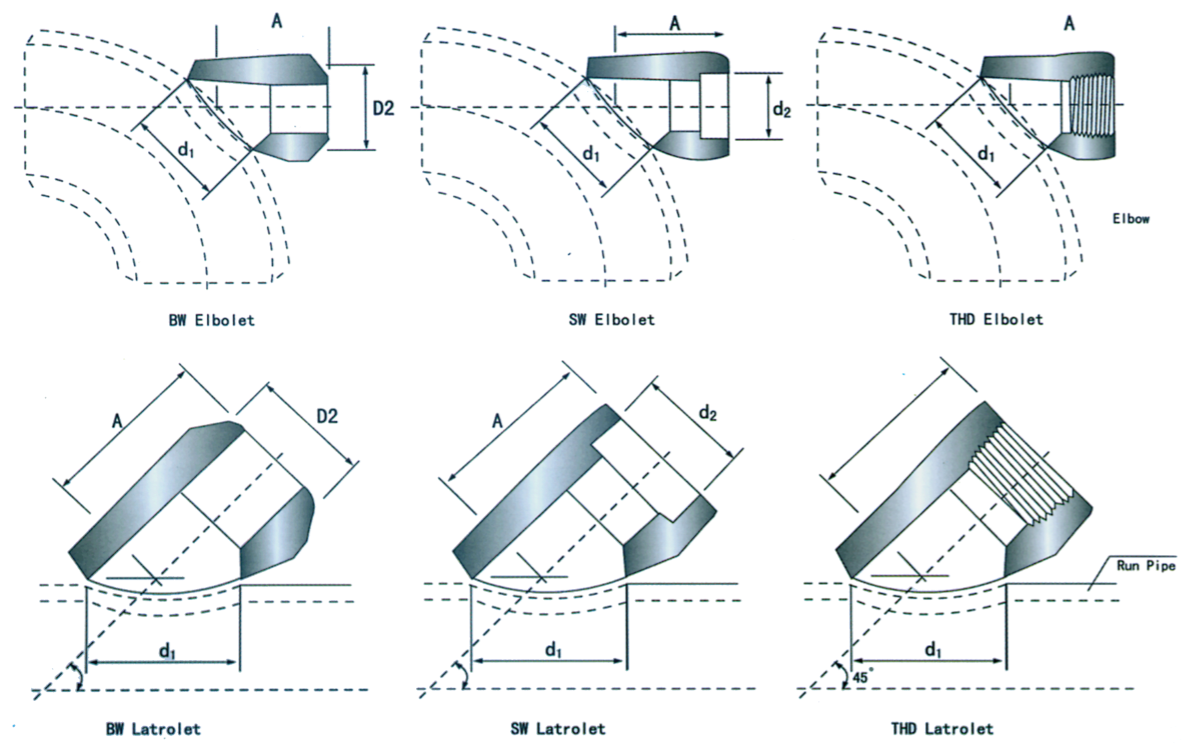

Elbolets and 45° Latrolets

|

|

| |

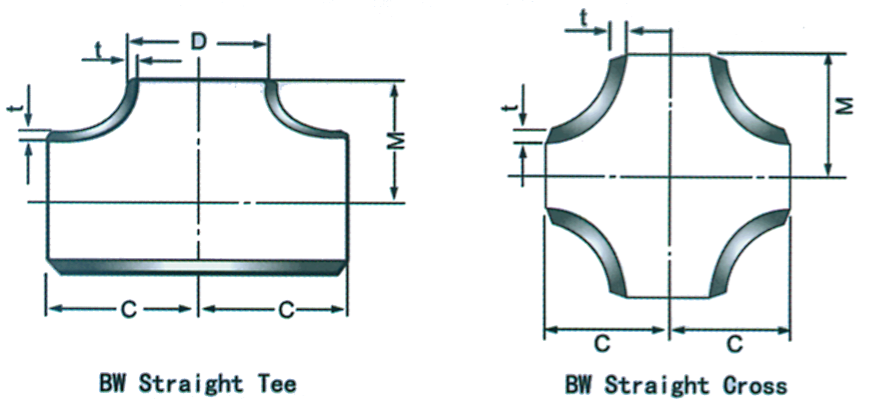

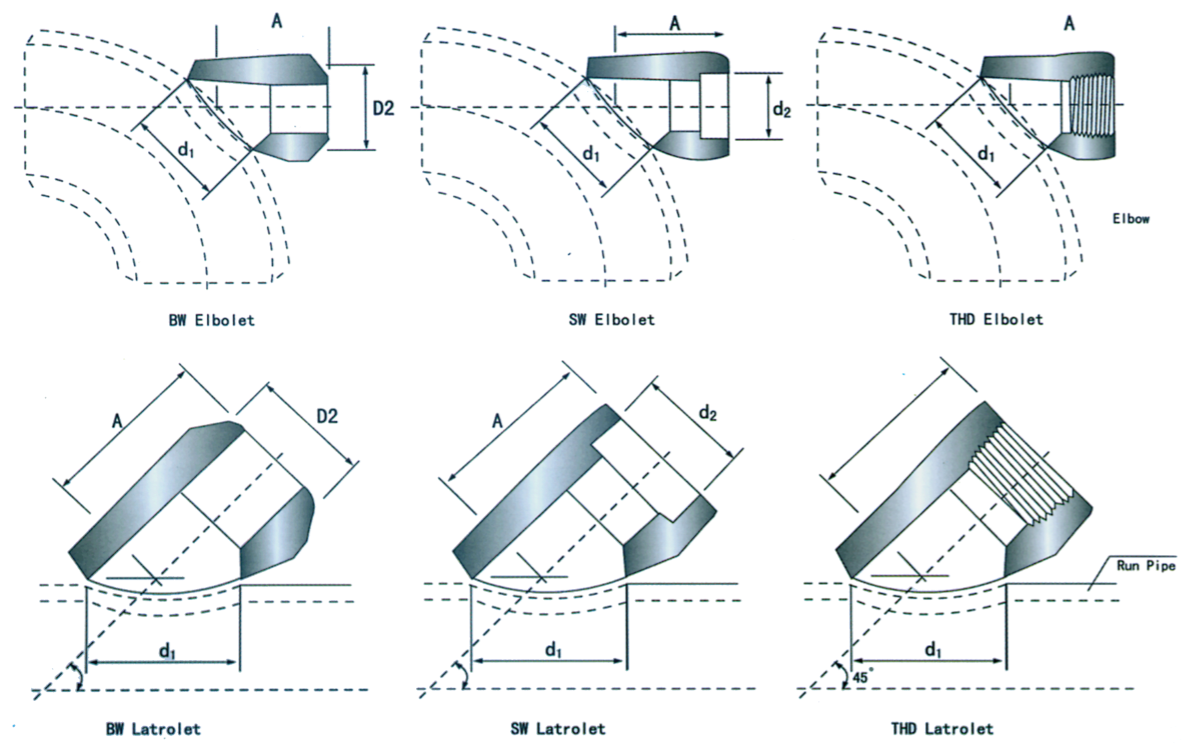

Seamless and Welded butt welding Fittings |

|

| |

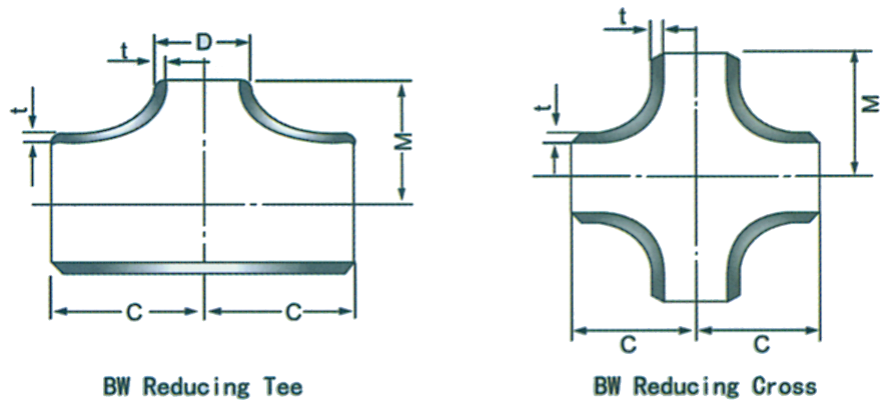

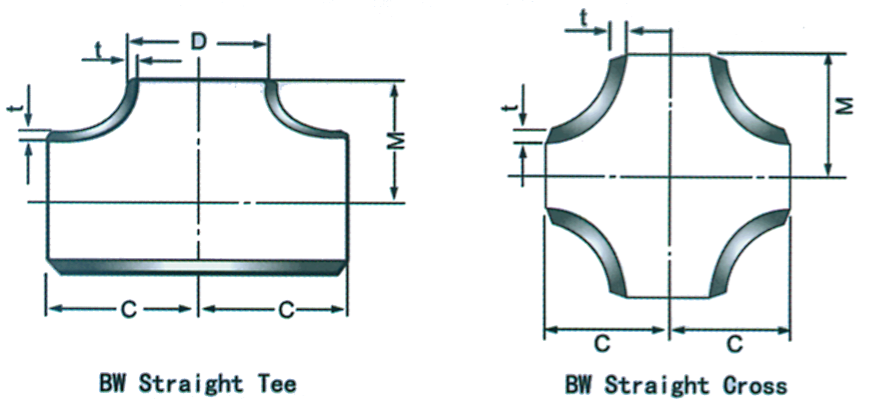

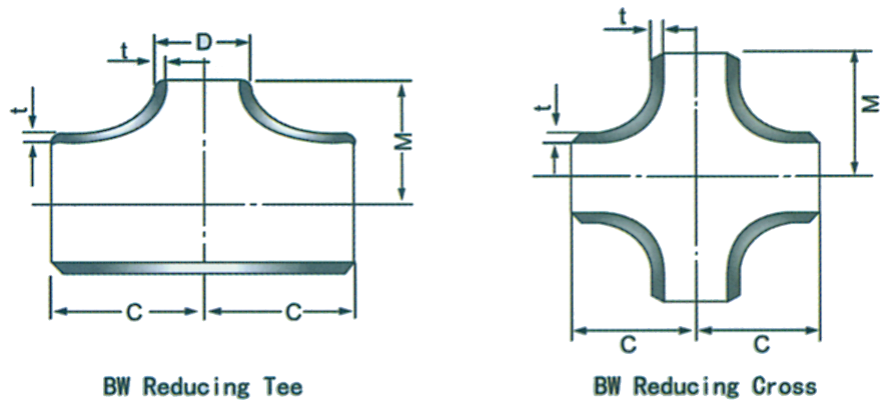

|

Products description:

45° 90° 180°LR&SR Elbow,Tee,Cross,

Reducer,Cap,Stub end,bend

Products Range: DN15-DN3000 seamless and welded

Wall thickness: Sch5-Sch160(Sch5s-S16s)

Manufacturing Standard: GB12459,GM/T13401,SH3408/3409,HG/T21635/21631, SY/T0510,ANSIB16.9, JIS 2312/2313, DIN 2605/2615/2617; Material:

0Cr19Ni9,0Cr18Ni9Ti,1Cr18Ni9Ti,0Cr18Ni12Mo2Ti, 00Cr18Ni10,00Cr19Ni11,00Cr17Ni14Mo2,304/304L, 316/316L,321,321H,317L,904L, 1.4541.1.4571.1.4301,1.4406

Duplex & Super Stainless Steel

ASTM1815 UNS31803(2205,00Cr22Ni5Mo3) UNS32750 (2507,00Cr25Ni7Mo4N); UNS32760

Carbon steel

Q235,20#,16Mn,16MnR,A234, WPB, WPL3/L6/L9,WPHY42,/46/52/56/60/65/70

Alloy steel

12CrMo,12CrMoV,15CrMo,10CrMo910,WP1,WP5,WP9, WP11,WP22,WP91

Others

Copper-Nickle Alloy,Titanium,Aluminum,Monel, Inconel,Hastelloy and other special material |

|

| |

|

|